Mastercut can manufacture highly detailed, intricate thin metal parts from your design for thousands of applications. Where these parts are chemically etched, we can incorporate design features such as fold lines, text and other details with no additional cost. This method of manufacture best suits small to intermediate volume job runs as the initial tooling cost is minimal and the price per part remains competitive.

The advantages of Photo Chemical Machining include...

- Burr Free - Unlike stamping and laser cutting, PCM leaves no burr

- Stress Free - The cutting process requires no heat and does not burn the edges of the metal

- Accuracy - Photographic accuracy on every part

- Low setup costs - Does not require expensive tooling which makes Photo Chemical Machining very cost effective for both short and long production runs

- Speed - in many cases, delivery can be made within a week and only a matter of weeks for larger orders

Parts are usually supplied in sheet form, held in by "micro-tabs" which allow the part to be easily removed or "twisted" from the sheet. This is usually convenient for the end user as it makes handling, shipping and storage very easy, while protecting individual parts. Optionally, Mastercut can remove all parts from the sheet if required.

Please view/download the 'Design Guidelines' for more information on how to get a quote and order your thin metal parts.

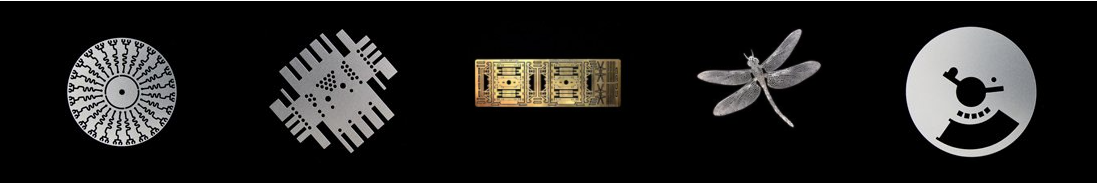

Encoder Wheels

Our chemical milling process allows us to produce a variety of Rotary Encoder Wheels. The range of inside and outside diameters and mounting holes is almost unlimited.

Using Photo Chemical Machining, virtually any combination and spacing of windows and bars can be achieved.

Mastercut also offer - Laser Cutting - PCM Etching - Plating & Forming

Download Mastercut's Brochure from the resources page for an overview of all products and services